N410

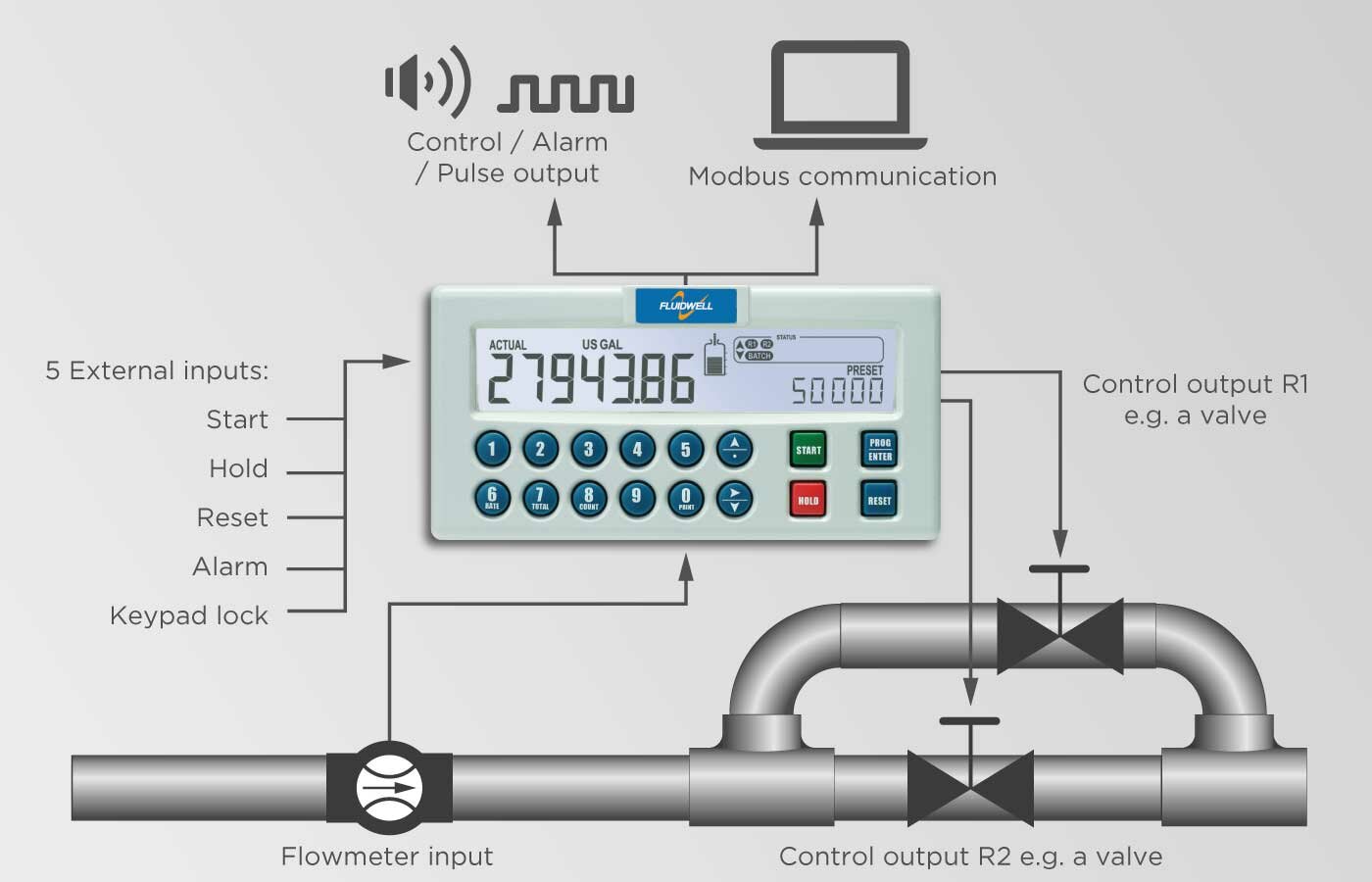

DIN Panel mount - Batch Controller

with numerical keypad, remote control inputs and 3 control / alarm / pulse outputs

Product description

The N410 batch controller distinguishes itself by its user-friendly features: Numerical keypad, clear programming menu structure, easy to read display and simple mounting enclosure. The numerical keypad allows simple and fast changing of the preset batch quantity. Fluidwell stands for simplicity and reliability and it is now available in this customer focused and application driven batch controller.

Advantages

- Save time and cost with the easy to operate numerical keypad.

- Familiar easy operation with the Fluidwell "Know one, know them all" configuration structure, saving time, cost and aggravation.

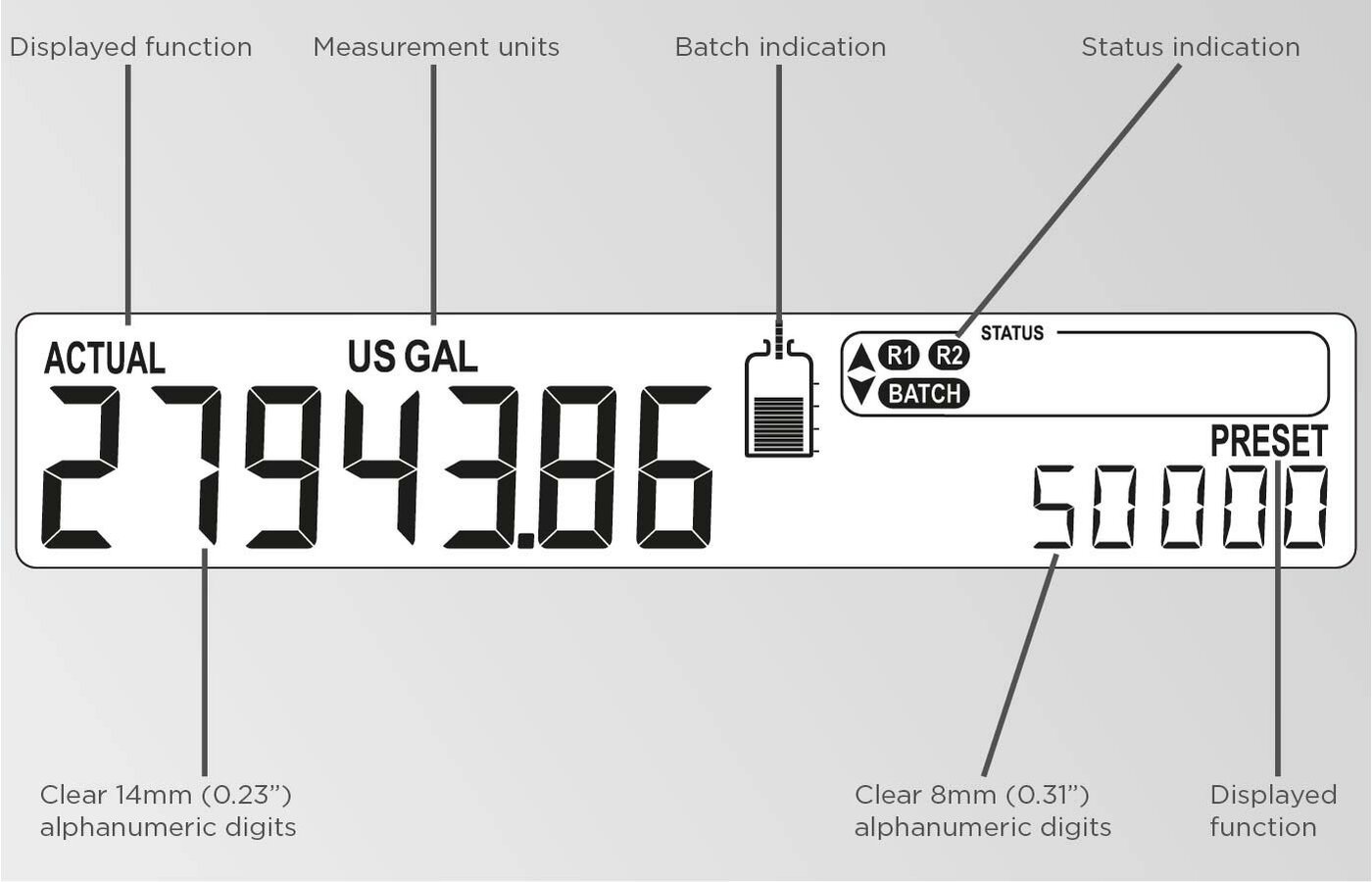

- Key information at a glance as the display simultaneously shows actual value, preset value, batch process indication, switch point indication and measuring units.

- Easy installation with the rugged aluminum DIN-size panel mount enclosure.

Downloads

Thank you

You will receive a email with the download link soon.

Features

- Full numerical keypad.

- Shows actual value, preset value, batch process indication, relay status indication and measuring units simultaneously.

- Five control inputs for remote START, HOLD, RESUME, keypad lock and external alarm.

- 7 large digits (14mm, 0.56") for actual value, flow rate and total.

- 10 smaller digits (8mm, 0.3") for preset value, accumulated total and batch count.

- Selectable on-screen engineering units for volumetric or mass: L, m³, USGAL, IGAL, ft³, bbl, kg, Ton, lb.

- The batch process can be visualized with the tank fill/spill symbol. This graphical representation can be enabled or disabled. When the batch overfills the preset quantity by 2.5% the graph will show two overspill arrows indicating this condition.

- Easy operation to enter a batch value and to control the process.

- Easy configuration with clear alphanumerical display.

- No-flow monitoring.

- Automatic overrun correction.

- Bright LED backlight.

- Auto backup of settings and running totals in EEPROM memory.

- Ambient temperature: -20°C to +60°C (-4°F to 140°F).

- Aluminum IP67 (NEMA Type4X) DIN front panel of 144 x 72mm (5.67” x 2.83”).

- A just-in-time back-up stores the latest batch information in case of a power failure.

- Various accessories are available for this product.

Applications

- Accurate batching or filling of liquids where the batch size changes frequently.

- The N-Series offers the perfect solution for batch control applications where a user-friendly instrument is required. Whether you focus on its clear display information, the very easy to operate numerical keypad or the easy menu-driven configuration structure, you've got to have a Fluidwell.

Product specifications

-

Signal Inputs

-

Flowmeter Inputs

- Pulse type inputs:

Reed-switch, open collector, NAMUR, NPN/PNP pulse, Sine wave (coil), active pulse signal.

- Pulse type inputs:

-

Status Inputs

- Remote control: start / hold / resume/ keypad lock / external alarm.

-

-

Signal Outputs

-

Pulse outputs

- Function: Scaled pulse output according to accumulated or batched total.

- Type: One configurable and field replaceable, very heavy duty, mechanical relay output (NO-NC) and one configurable transistor output.

-

Alarm outputs

- Function: Switched in case of a no-flow, external or system alarm.

- Type: One configurable and field replaceable, very heavy duty, mechanical relay output (NO-NC) and one configurable transistor output.

-

Analog outputs

- None.

-

Control outputs

- Function: Relay 1 is fixed as the main batch control relay. Relay 2 and the transistor output can be configured as 1- or 2-stage batch control output.

- Type: Two field replaceable, very heavy duty, mechanical relay outputs (NO-NC) and one configurable transistor output.

-

-

Supply

-

Power Supply

- 24V DC.

- 110 – 230V AC.

-

Sensor Supply

- 8.2 – 12 – 24V DC.

-

-

Hazardous Area

-

Intrinsically Safe

- For safe areas only, for Intrinsically Safe applications we recommend the F-Series batch controllers.

-

-

Communication

-

- Function: All process data and settings can be read and modified through the communication link.

-

- Protocol: Modbus RTU.

-

- Interface: RS232 or RS485 2-wire.

-

Questions and answers

No questions have been asked about this article yet.

Ask a questionThank you

Your question has been forwarded to our support team.

We will answer it as soon as possible.