F120

Safe area / Intrinsically safe - Flow rate Controller (Temporarily not available)

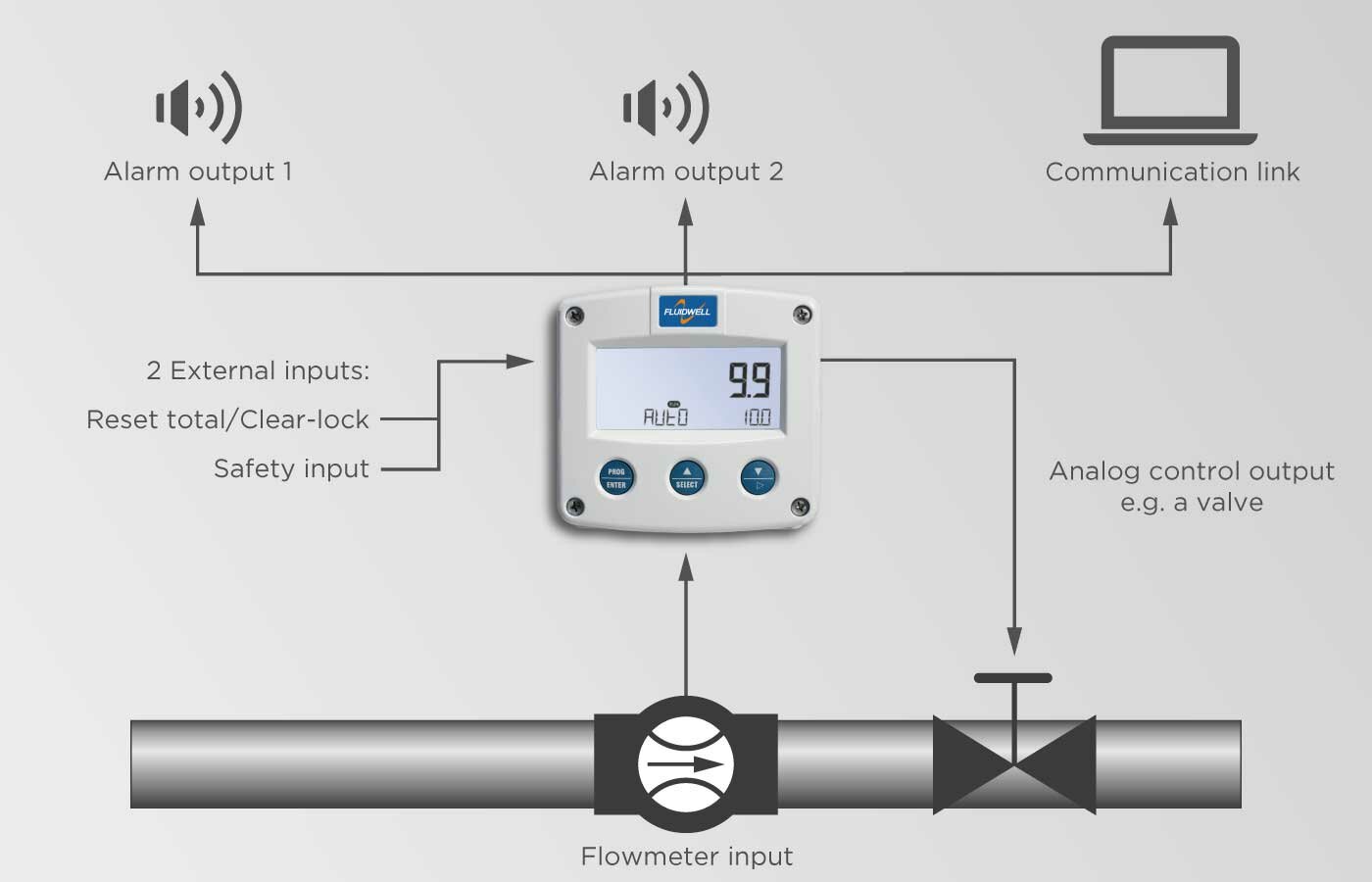

with analog control output and high / low alarms

Product description

This product has "Limited Availability", please consult your local supplier for prices and lead times. The F120 single loop controller has been designed to offer outstanding control performance and provide a reliable solution for a wide variety of flow control applications. The single loop flow controller accepts most pulse inputs from flowmeters and has a 4 - 20 mA output for controlling a valve or pump. The F120 is part of the Fluidwell process controller family and is the alternative for local control loops.

Advantages

- Robust aluminum or stainless steel 316L field enclosure (IP65, IP67 / NEMA Type4X) .

It is so rugged, a truck can even stand on it! - Intrinsically Safe available - ATEX and IECEx approval for gas and dust applications.

- Familiar easy operation with the Fluidwell "Know one, know them all" configuration structure, saving time, cost and aggravation.

- Very diverse mounting possibilities: walls, pipes, panels or directly onto outdoor sensors.

Downloads

- Datasheet - F120

- General F-Series Leaflet

- Success Story: Beverage filling

- F1-Series Declaration of Conformity

- ATEX certificate

- IECEx certificate

- Cenelec certificate (2002)

- Annex 1 to NL/DEK/ExTR11.0033/01

- F1-Series Certificate binder

- CCOE certificate (India)

- Fluidwell Modbus Communication Guide

- F1-Series Modbus Troubleshooting Guide

- Datasheet EX d enclosure (option XF)

- Accessories & spare parts

- F120-P Manual

- F120-A Manual

Thank you

You will receive a email with the download link soon.

Features

- Two control modes:

- Hand (manual valve control)

- Auto (control flow to obtain the desired flow rate) - Bumpless transistion between the control modes.

- Flow rate monitoring: two alarm values can be set: low and high flow rate alarm.

- Alarm values can be changed by the operator or they can be password protected.

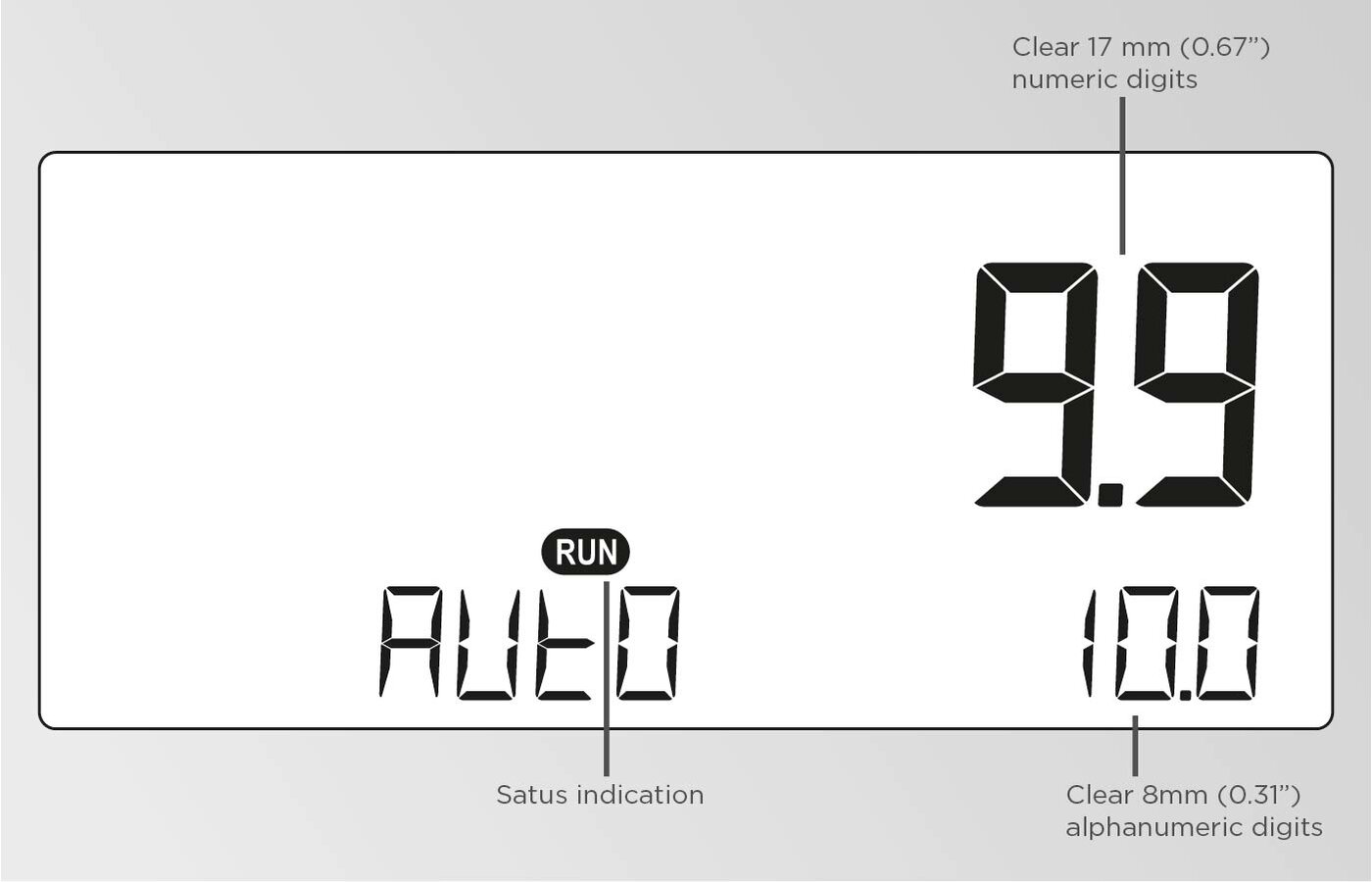

- Displays flow rate, alarms, setpoint and total.

- Safety mode input to place the valve in a safe position

- Flow rate: seven 17mm (0.67") digits.

- Total - resettable: seven 17mm (0.67") digits.

- Displays clear alarm messages.

- LED backlight.

- Intrinsically safe according ATEX and IECEx.

- GRP, Aluminum or high grade stainless steel enclosure.

- Auto backup of settings, totalizer value, setpoint and control mode in EEPROM memory.

- Ambient temperature: -40°C to +80°C (-40°F to 176°F).

- Various accessories are available for this product.

Applications

- Applications where a constant liquid or gas flow is desired without the need to manually control the flow.

- The F-Series is your first and best choice for field mount indicators in safe and hazardous area applications. Especially in harsh weather conditions like rain, snow, sandy deserts, salty atmospheres and temperatures between -40°C up to +80°C (-40°F up to 176°F).

Product specifications

-

Signal Inputs

-

Flowmeter Inputs

- Pulse type inputs:

Reed-switch, open collector, NAMUR, NPN/PNP pulse, Sine wave (coil), active pulse signal.

- Pulse type inputs:

-

Status Inputs

- Remote control: external reset for clearing total.

- Remote control: Safety mode which stops the control process and places the valve in a safe position.

-

-

Signal Outputs

-

Pulse outputs

- None.

-

Alarm outputs

- Function: Two alarm outputs for low and high flow rate alarm (not available with analog input).

- Type: Two passive NPN transistors, active PNP transistors or isolated electro-mechanical relays.

-

Analog outputs

- Function: Control output to position the valve of the flow.

- Type: One passive isolated, floating or loop powered 4 – 20mA output or one active (0)4 – 20mA or 0 – 10V DC output.

-

-

Supply

-

Power Supply

- Long life Lithium battery.

- 4 – 20mA Output loop-powered.

- 8 – 24V AC/DC.

- 115 – 230V AC.

- Basic: 8 - 30V DC.

-

Sensor Supply

- 3.2, 8.2, 12, 24V DC.

-

-

Hazardous Area

-

Intrinsically Safe

- ATEX:

Gas: II 1 G Ex ia IIB/IIC T4 Ga

Dust: II 1 D Ex ia IIIC T200 100 °C Da - IECEx:

Gas: Ex ia IIC/IIB T4 Ga

Dust: Ex ia IIIC T200 100 °C Da

- ATEX:

-

Explosion Proof

- ATEX/IECEx:

Gas: II 2 G Ex db IIB+H2 T5 Gb

Dust: II 2 D Ex tb IIIC T80°C Db

- ATEX/IECEx:

-

-

Communication

-

- Function: All process data and settings can be read and modified through the communication link.

-

- Protocol: Modbus RTU.

-

- Interface: RS232 / RS485 2-wire or 4-wire / TTL.

-

- HART communication is available with the F018 Flow rate Monitor / Totalizer.

-

Questions and answers

No questions have been asked about this article yet.

Ask a questionThank you

Your question has been forwarded to our support team.

We will answer it as soon as possible.